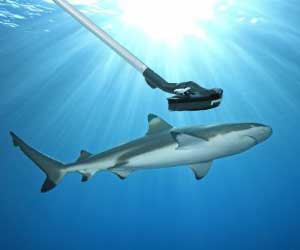

Natural inspiration for innovation in cleaning technology

Among all the exciting swimming competitions last year at the 2012 Summer Olympics was a report about the ban on Speedo Fastskin and other similar high-tech, high-performance swimsuits. Inspired by the sandpaper-like texture of the skins of sharks, the Fastskin in particular was created by Speedo to reduce drag in water and shave critical seconds off record times; one reason it was banned was due to concerns that poorer countries didn’t have access to this swimsuit technology.

[EasyDNNnewsToken:Left Justify Embed 300 x 250]

From the Deep of the Sea

The Speedo Fastskin is one example in the growing field of Biomimetrics, which studies how nature can be copied to solve human problems. Sharkskin in particular is being studied because these fast and carnivorous predators of the sea have a microscopic texture to their skin which, in addition to making them slice through the water, also makes them highly resistant to barnacles, algae and most interestingly, bacteria.

Researchers have discovered shark skin is made of shingles of “denticles,” or surface ridges, which are invisible to the eye and undetectable by touch. The patterns in which these shingles grow help them deflect bacterial growth. Sharklet Technologies has copied this unique, bacteria-resistant pattern to create a man-made shark skin that can reduce bacterial growth by 90 to 99% depending on the type of bacteria. The pattern on the surface discourages germs that come in contact with the surface from attaching to it.

Sharklet is working with hospital, classroom and office technology manufacturers to develop surfaces using this anti-bacterial material. However, while non-toxic, the mats and skins wear out and must be replaced after about 90 days.

A Silver Lining

While the antimicrobial effect of silver is well documented and has been used in healthcare for many years, the discovery that copper and its alloys have superior antimicrobial properties and are more inexpensive than silver have prompted their wide-spread use in the health care industry.

As the only solid antimicrobial touch surface approved by the EPA, copper has continuous and ongoing antimicrobial action. Copper’s antimicrobial effect never wears out – even with repeated wet and dry abrasion, recontamination, and natural tarnishing. As copper is both natural and safe to use, it is not harmful to people and the environment since no chemicals are added to it. Copper is also completely recyclable.

A Light-bulb Moment

Imagine simply turning on the light in a room to reduce germs and disinfect the surfaces. That’s the theory behind a new concept that is still in research: the combination of titanium dioxide and light.

Titanium dioxide can be embedded into surface materials or applied in a film to non-porous surfaces and then activated with ultraviolet light to kill any germs that happen to be present. This technology is still in the research stage toward becoming a hot item in the food service and kitchen surface industries.

A Tiny Army

Futuristic movies used to tease us with tiny robot armies that could take over the world, but nano-science is already in use, both in nanoparticle chemical and nanotechnology machines. We already have several products available as antibacterial nanoparticle coatings for surfaces such as stainless steel or plastic. These coatings can contain chemicals which inhibit or kill germs that come in contact with the surface, although they do wear off and need to be reapplied on a regular basis.

Cleaning Antimicrobial Surfaces

So how are these high tech surfaces cleaned? Aha! That’s the key word: cleaned. Because of their antibacterial and antimicrobial properties, antibacterial surfaces generally require only cleaning – keeping them wiped down and free of major debris with a neutral cleaner. After all, the surfaces will do their job of inhibiting or killing germs.

As suggested with all surfaces, natural or synthetic, know their composition and their manufacturer-recommended cleaning methods. Test your products and methods on any surface you aren’t familiar with; never be afraid to tell a client that you can’t guarantee that your cleaning won’t damage a surface you can’t identify. Being a knowledgeable, trained and even certified cleaning technician is the result of continually learning about the new surfaces being used in the indoor environment and the effective and safe products and cleaning methods for maintaining those surfaces.